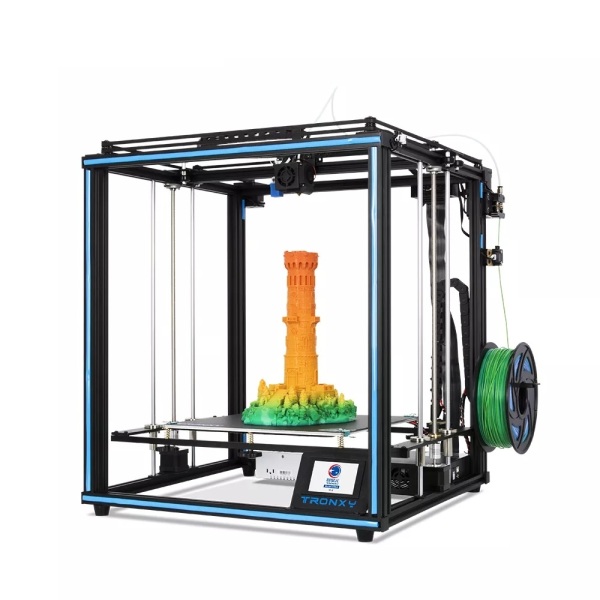

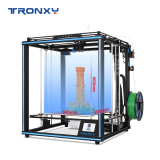

TRONXY X5SA 24V 3D Printer 330*330*400mm Item NO.: X5SA

- Ships From

- Czech(To EU Country Only) United State(To US Only) Australia (To AU Only) Russia(To RU Only) China UK ( To UK Only) Canada(TO CA Only) Brazil Warehouse(To BR Only) (Individual tax number required)

- Quantity

Copy and share this link on social network or send it to your friends

Copy- 【Quality pulley updated】,

- 【Completed wire connection】,

- 【Bowden extruder】,

- 【Auto leveling】,

- 【Double fans design】,

- 【Filament run-out detection】,

- 【Quality stepper motor】,

- 【3.5 inch touch screen】,

- 【It is a DIY assembly machine. It is more suitable for some enthusiasts with 3D printing experience to buy. Of course, if you are a DIY enthusiast or a beginner who is willing to spend a lot of time to assemble and learn 3D printing, you can also choose to buy】

| Product Name | TRONXY X5SA 24V 3D Printer 330*330*400mm |

| Item NO. | X5SA |

| Weight | 15 kg = 33.0693 lb = 529.1094 oz |

| Category | GMC |

| Tag | TRONXY X5SA , X5SA |

| Brand | Tronxy |

| Creation Time | 2019-11-04 |

The Tronxy X5SA is one of the new 3D printers kits which seems to hit a sweet spot with customers worldwide.

The Tronxy X5S is the bigger brother of the Tronxy X3SA and has overtaken it in popularity.

Since early 2018, it has become one of the best-selling 3D printers on stores like Gearbest and Aliexpress.

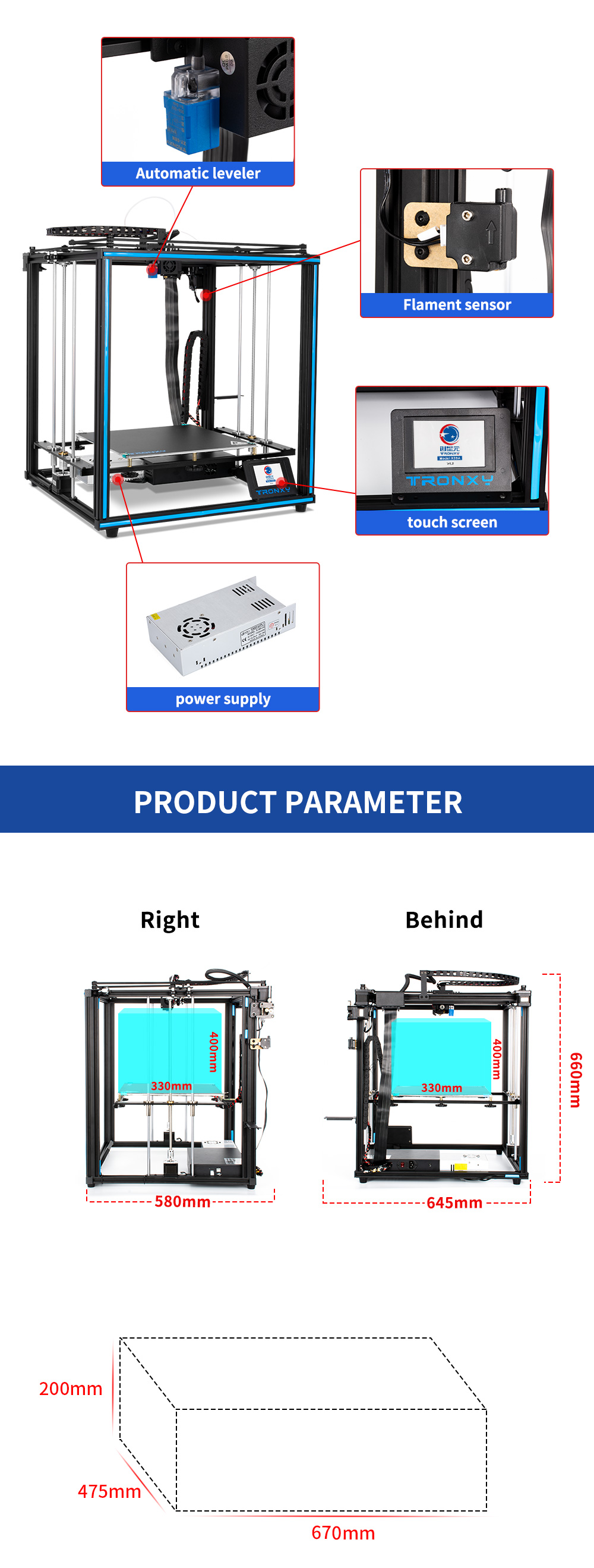

The most obvious feature of the machine is its size. A 3D printer that offers a build volume of 330 x 330 x 400mm for under $300 sounds like a very good deal – but is it really?

The specifications for the Tronxy X5S read very similarly to most low-cost 3D printer kits on the market. Here are the specifications, as to be found on the official information sheet:

Technology: FDM (Fused Deposition Modeling), single extruder

Build Volume: 330 x 330 x 400 mm

Display: 3.5inches full color touch screen

Layer Resolution: 0.1 – 0.4mm

Nozzle/Filament Diameter: 0.4 mm / 1,75mm

Connectivity: USB, SD Card

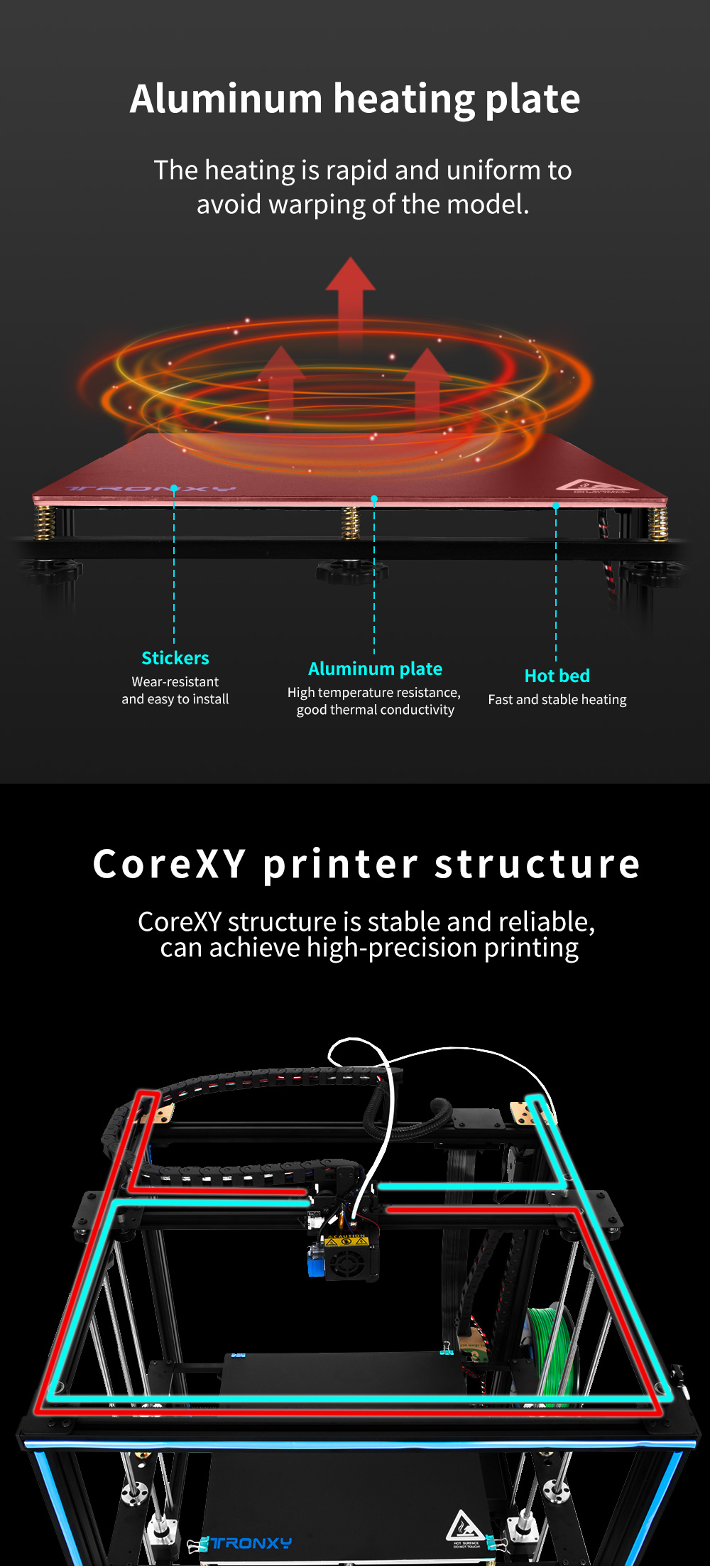

Heated Bed: Yes

Print Speed: 20-150 mm/s

Operational Extruder Temperature: max 270C

Operational Heatbed Temperature: max 100C

Nozzle temperature: ≤260°c

Environmental temperature: 8-40°c

Environmental humidity: 20-80%

Slicing software: Tronxy Software

Files format: STL.OBJ.DAE.AMF.G-CODE

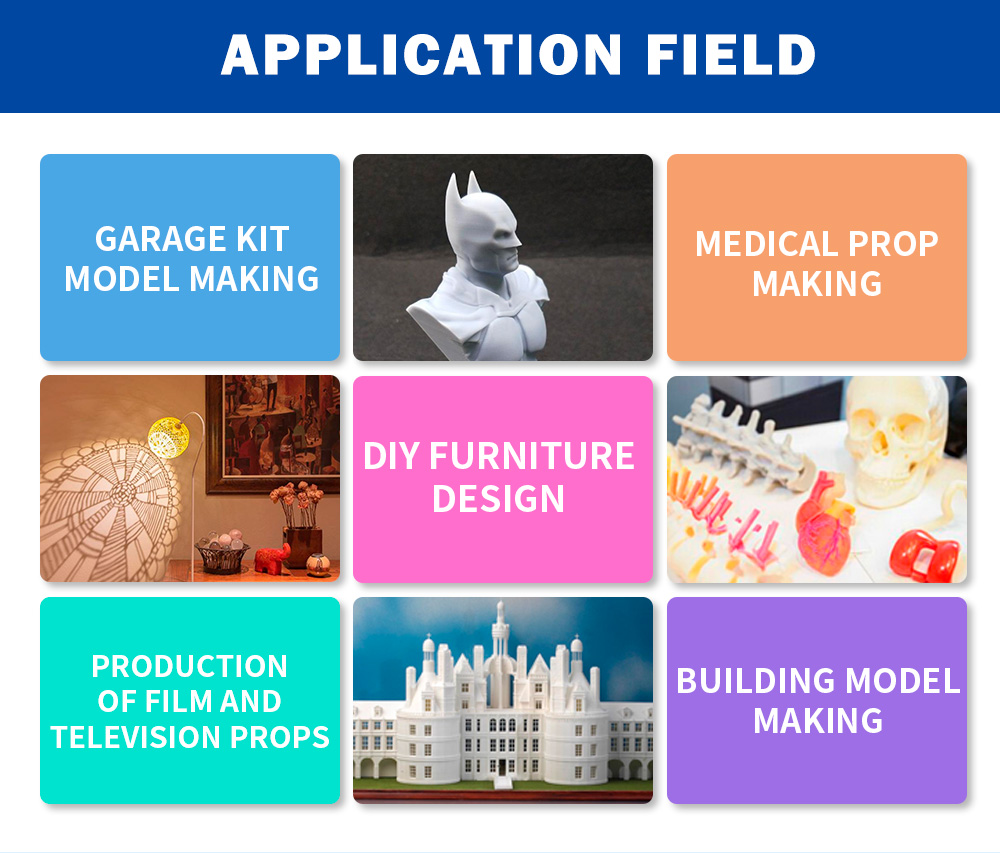

Materials support: PLA.ABS.HIPS.WOOD.PC.PVC

Operation system: WINDOWS/MACOS/LINUX

Certificate: CE FCC

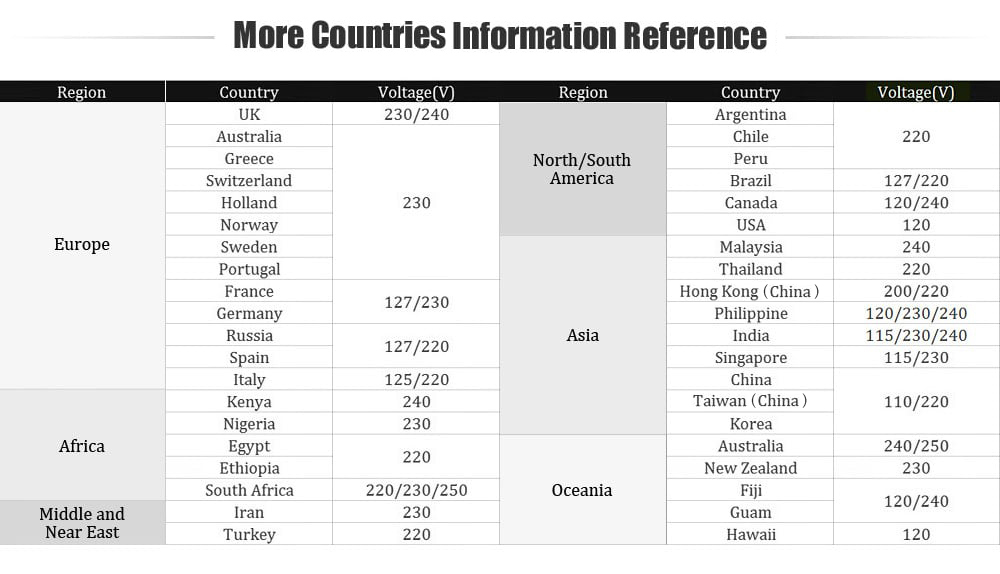

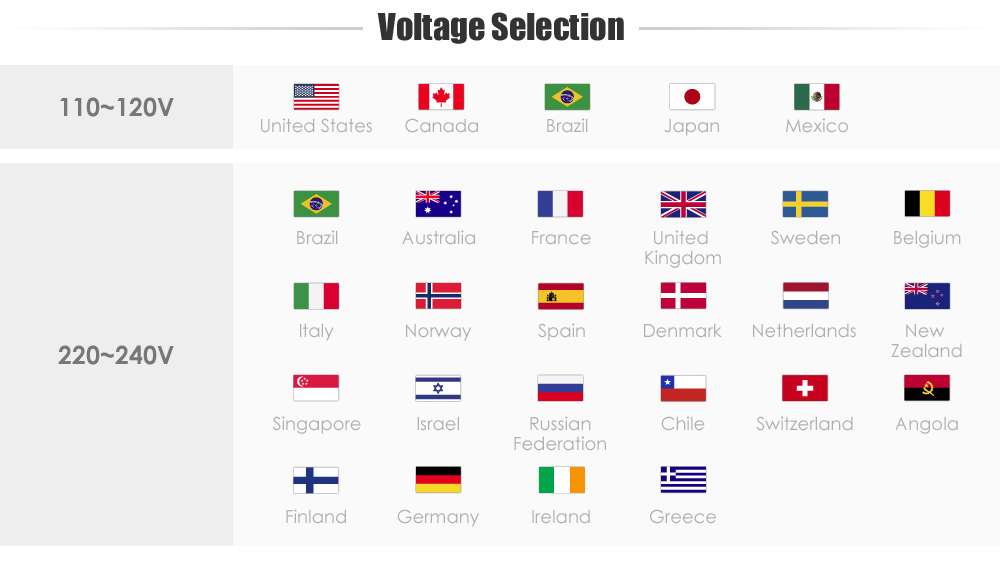

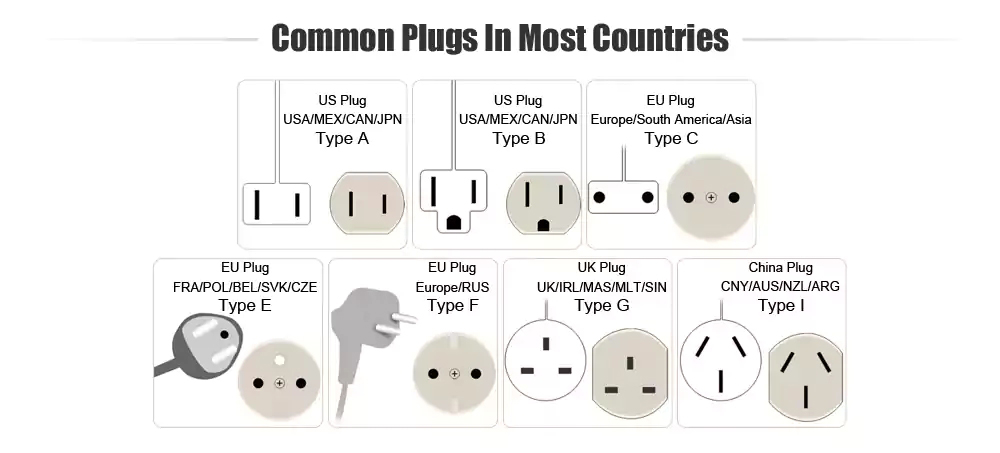

Power input: 110v/220v ac,50/60hz

Power output: 360w Position accuracy: X/Y0.0125mm,Z0.02mm

Packing weight:13.2kgs

Machine size: 710*653*660mm

Packing size: 650x440x190 mm

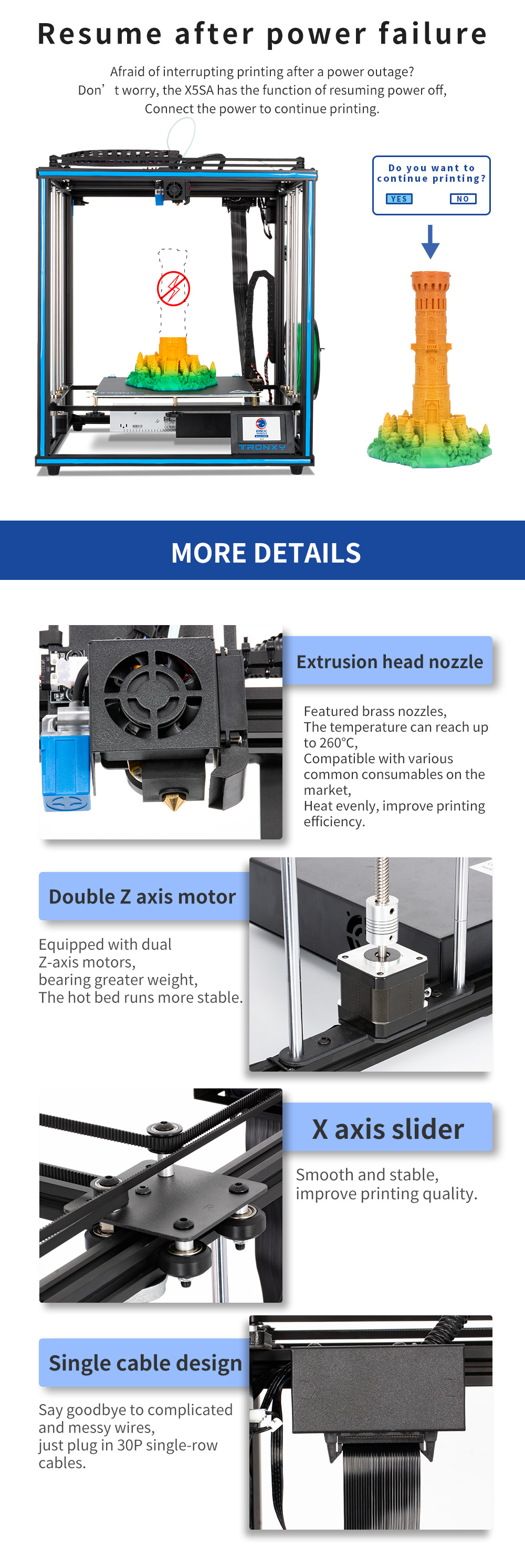

Power failure resume to print: Support

Filament run out detector: Support

Hotbed temperature: Support

Tronxy X5SA CoreXY 3D Printer Kit

Main Features:

- Large build size size: 330*330*400mm

- Highly durable aluminium profile

- New updated touch screen, more function for choice

- No warping issues

- Supports auto leveling.

- With Power failure resume print function, don't worry even the power is off

- The mainboard support Filament run out detection, but need to buy the sensor by yourself

- Support WIFI connection( the WIFI module should buy seperately)

- With Dual Z-axis rod design stable printing makes reassuring

- Industrial chain design wires more beautiful and safety

- High-power current source supply 360W. Working voltage: 24v.

- Easy to assemble.

You May Also Like

-

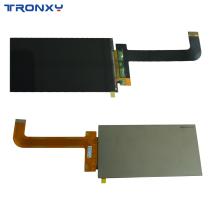

Tronxy Uitrabot Light curing 5.5/6.08 inch 2K s...US$ 49.05 US$ 68.60

-

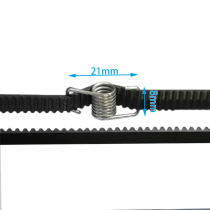

Tronxy Z-axis timing belt adjuster with Z axis ...US$ 15.61 US$ 21.90

-

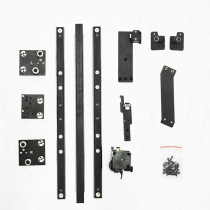

Tronxy X5SA/X5SA-400 upgrade to X5SA Pro/X5SA-4...US$ 128.95 US$ 162.20

-

Tronxy Parts Adapter Board with 82cm Cable BlackUS$ 15.00 US$ 25.00

-

Hotbed stickerUS$ 10.83

Newsletter

- Company Info

- About Us

- Contact Us

- News Center

- Support Center

- User Center

- Register

- My Account

- My Orders

- Tracking Order

- Forget Password

Copyright © 2012-2023 Tronxy 3D Printer All Rights Reserved.

2021-11-12

2021-09-24

2021-08-24

2021-08-16

2021-08-10

2021-07-14

2021-07-09

2021-07-08

2021-05-02

2021-05-02

2021-04-09

2021-04-09

2021-04-08

2021-03-29

2021-03-20

2021-03-15

2021-03-15

2021-03-09

2021-02-22

2021-02-19