3D Printer - Advantages and Disadvantages of Broden Extruder and Direct Extruder2020-11-20

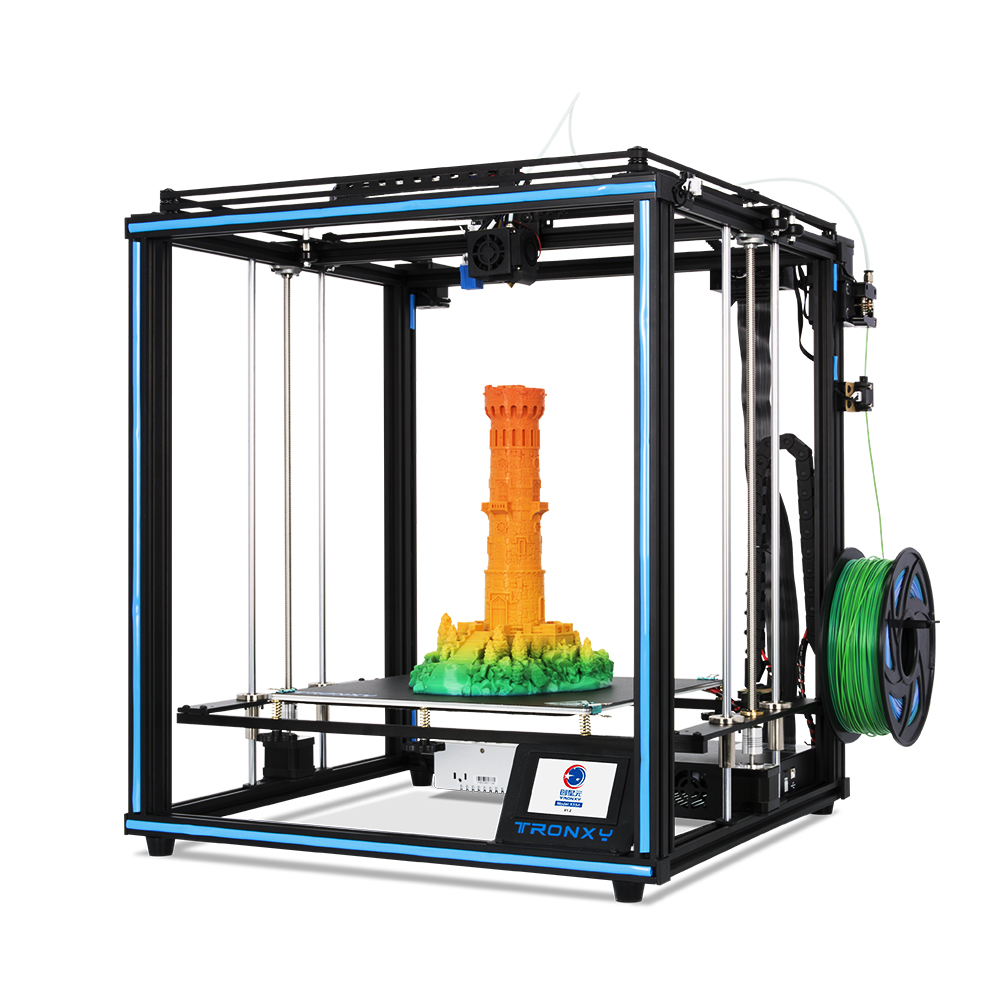

Common desktop 3D printers can be divided into i3, box structure, Core xy, delta, etc. according to the structure.

But according to the feeding method, it can be divided into two types of machines: Broden Extruder and Direct Extruder.

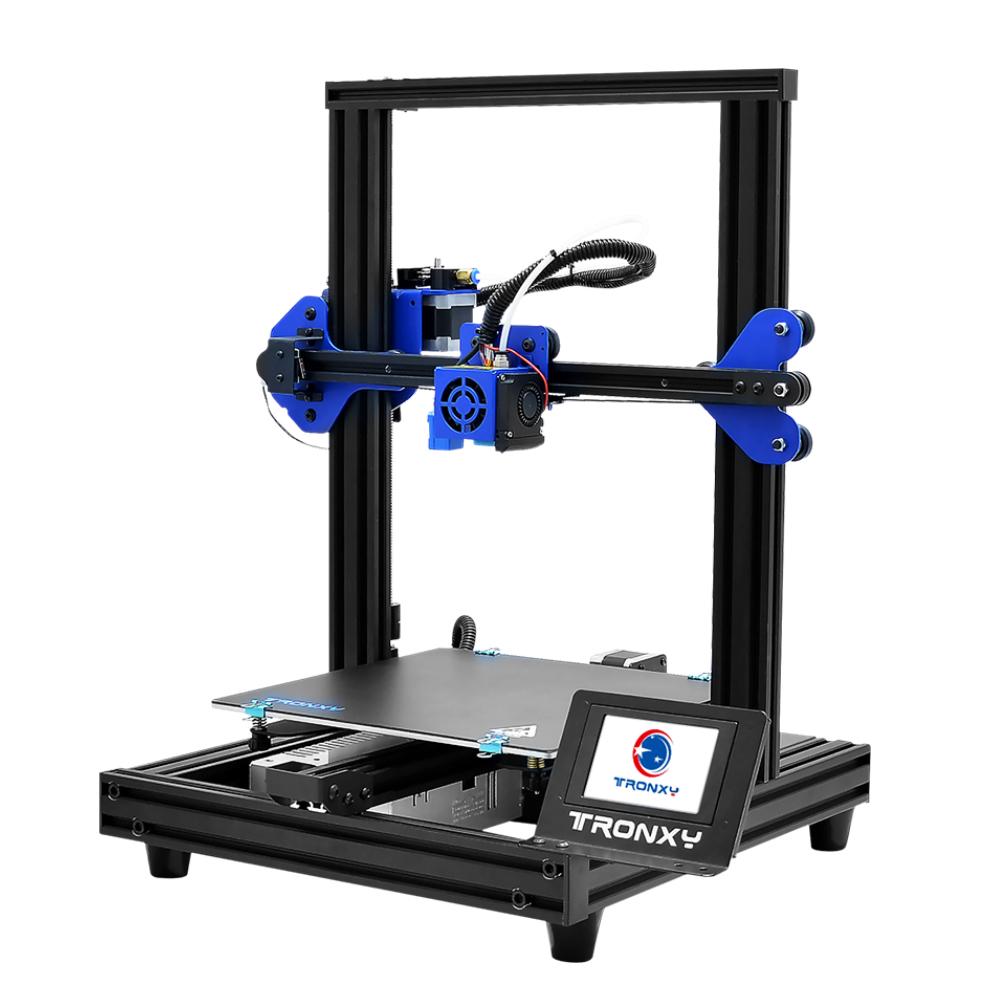

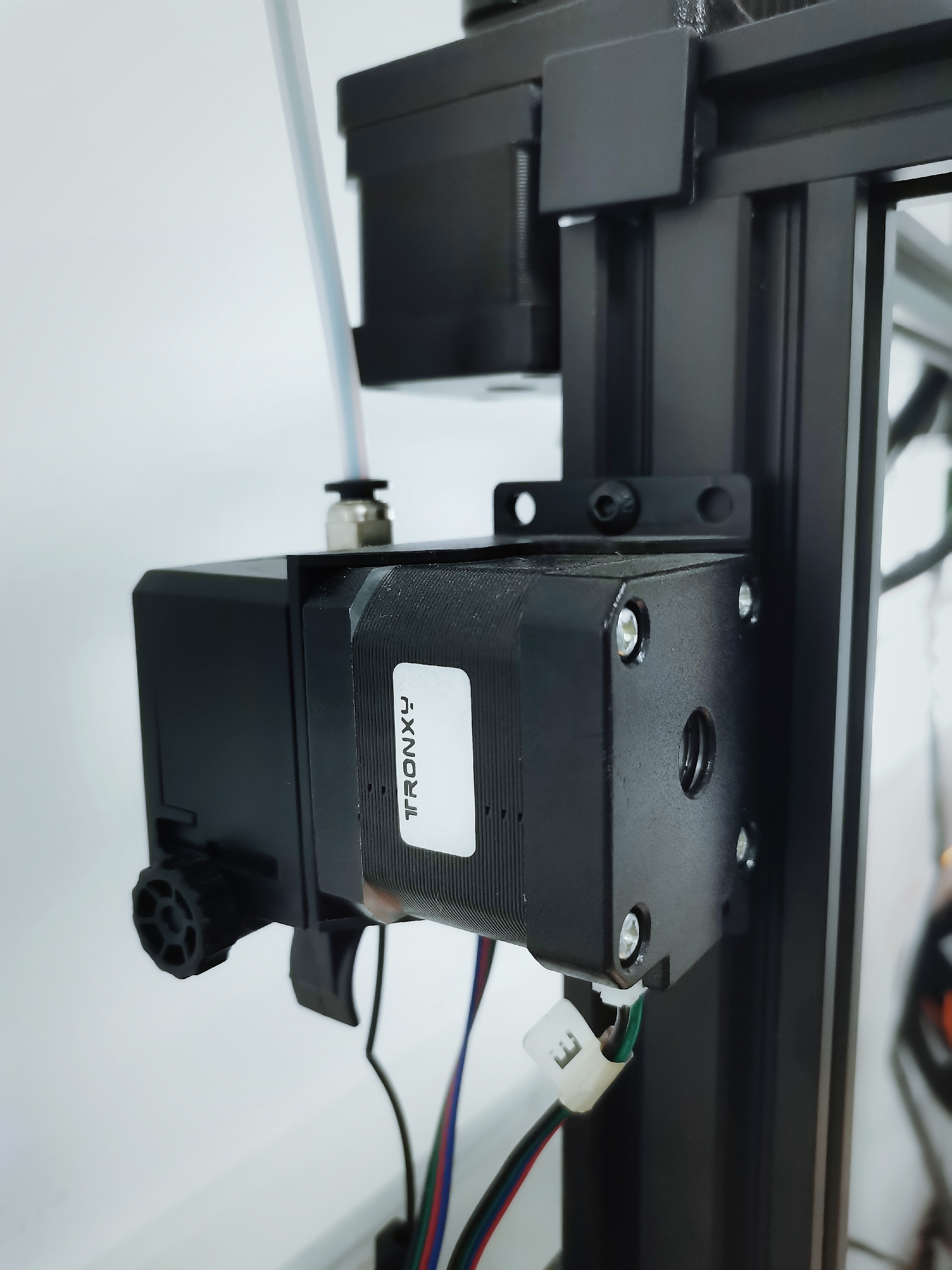

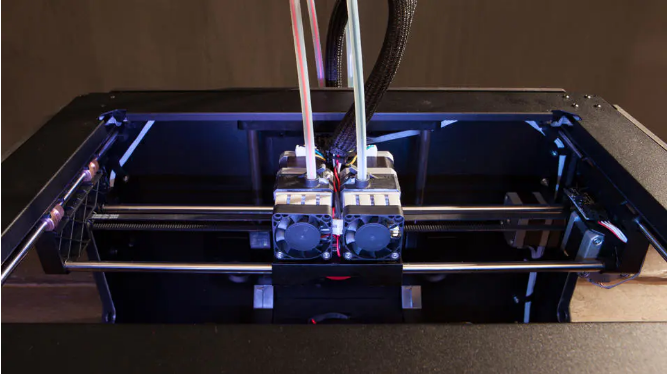

Broden Extruder

In this type of machine, the extruder and stepper motor are generally installed on the machine shell, and the nozzle is fed remotely through a Teflon tube.

For example, the extruder in the picture above is.

Common models: X5SA, X5SA PRO, X5SA-2E, etc.

Advantage:

1. The nozzle is light in weight, small inertia, and more precise in moving and positioning;

2. The nozzle moving speed can reach 200~300mm/s, so its printing speed can also be very fast;

3. The nozzle and extruder are separated for easy maintenance.

Disadvantage:

1. The feeding distance is long, the resistance is large, and the stepping motor responsible for extrusion is required to have a larger torque;

2. The extruder and the nozzle need to be connected with a Teflon tube and a pneumatic connector, which is more prone to failure than direct extruder;

3. Filaments and Teflon tubes have a certain degree of flexibility, and the general pneumatic joints also have a certain amount of movement space, so the required withdrawal distance and speed are greater, which is not as accurate as the direct extruder;

4. The distance between the extruder and the nozzle is long, so the filaments in the feeding tube are more difficult to use up.

5. The filament change is not very convenient, especially when the printing process does not pause, the new filament is over the old filament, and the filament head cannot be withdrawn when it is in the feeding tube.

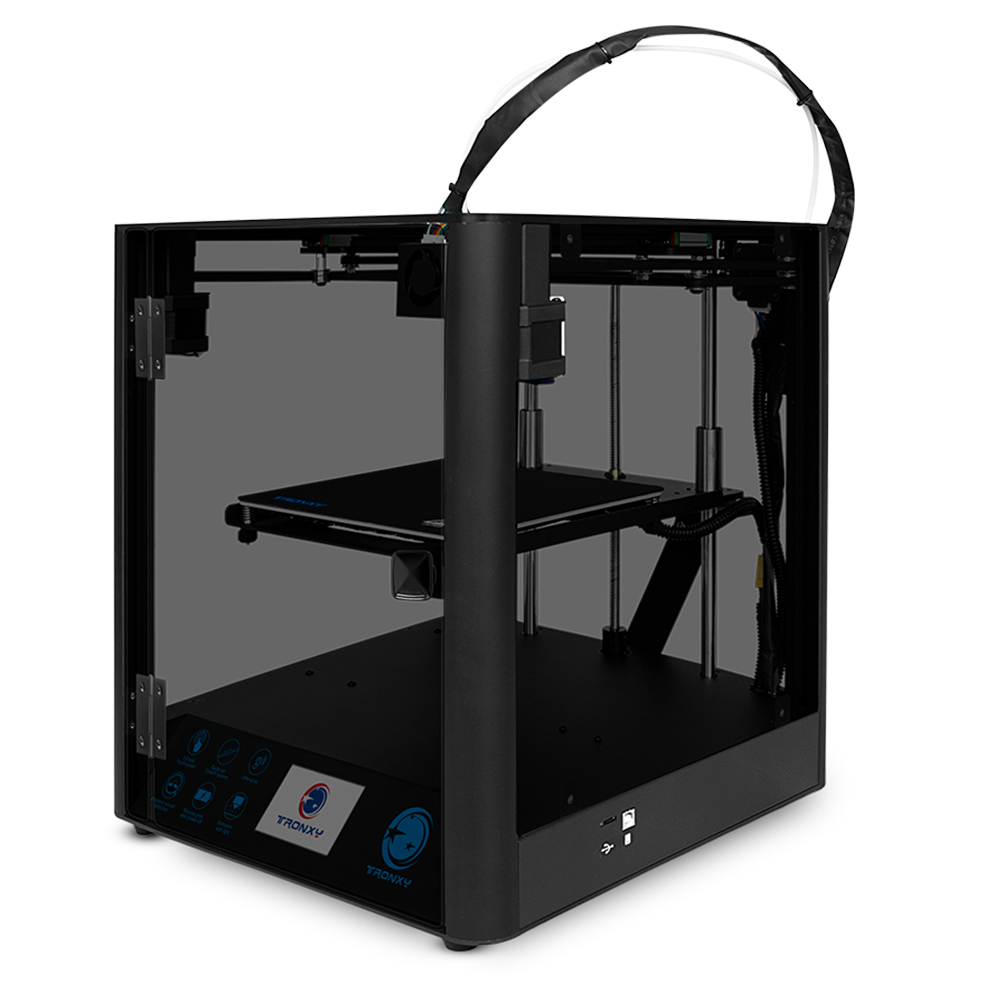

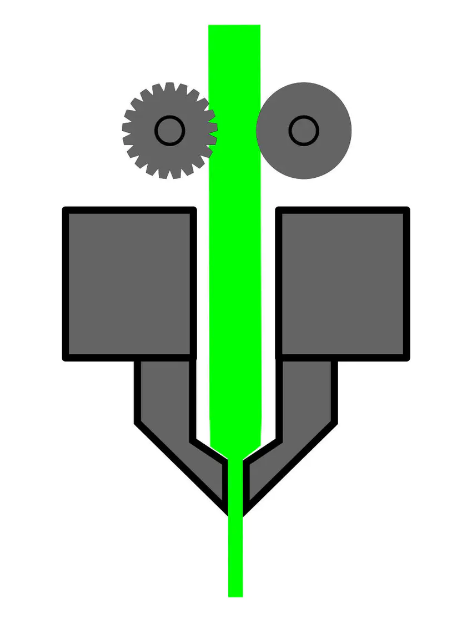

Direct extruder

For this type of machine, the extruder and stepping motor are usually installed on the nozzle and feed the nozzle directly.

Advantage:

1. The control of the feeding amount is more accurate than remote extrusion, and the withdrawal is more accurate;

2. The torque requirement of the extrusion stepper motor is relatively low;

3. Easy to change filaments.

Disadvantage:

1. The hotend of the nozzle, extruder, stepper motor, and cooling fan are integrated, which is inconvenient for disassembly and maintenance;

2. The print head is heavier, especially the dual-nozzle printer, which has large inertia when moving, and it is relatively difficult to accelerate and decelerate, so a lower printing speed should be used to ensure accuracy;

3. The heavier print head puts more pressure on the optical axis or guide rail, and it is easy to bend it for a long time. Usually, the print head is lower in the middle of the optical axis than on the two sides, which makes it difficult to level the platform.

In conclusion:

For the time being, it is almost impossible to have both speed, accuracy and support for comprehensive printing materials at the same time, so that different extrusion methods can be selected according to the needs.

If possible, it is better to prepare two different 3D printers to meet different printing needs.

Newsletter

- Company Info

- About Us

- Contact Us

- News Center

- Support Center

- User Center

- Register

- My Account

- My Orders

- Tracking Order

- Forget Password

Copyright © 2012-2023 Tronxy 3D Printer All Rights Reserved.