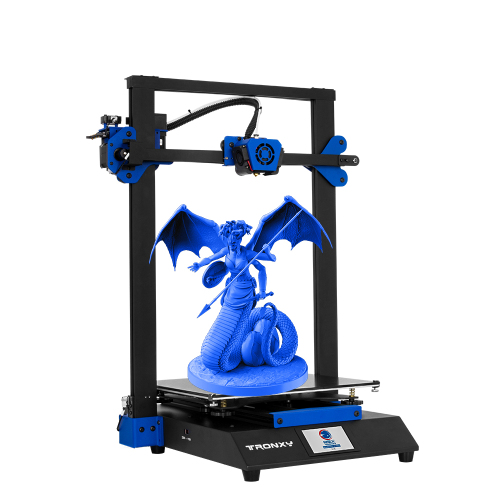

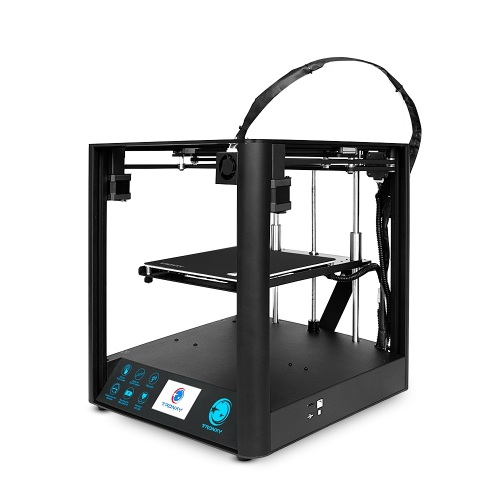

FDM 3D Printer (11)

FDM – Fused Deposition Modeling

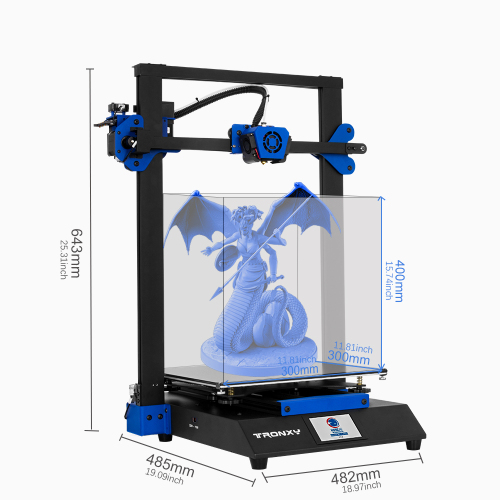

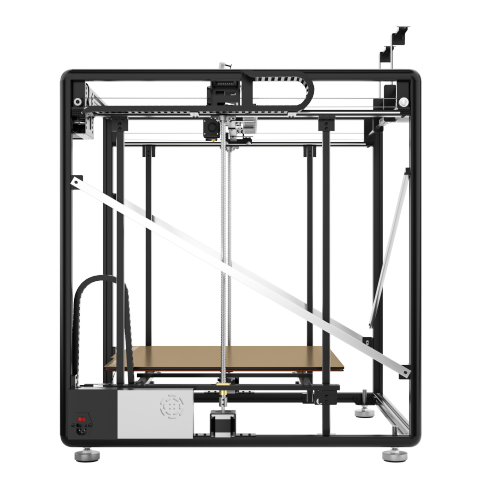

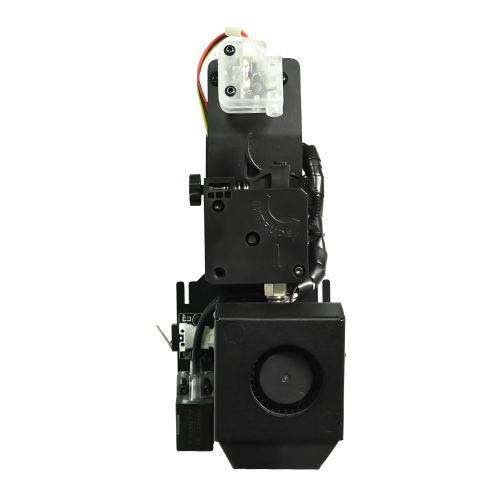

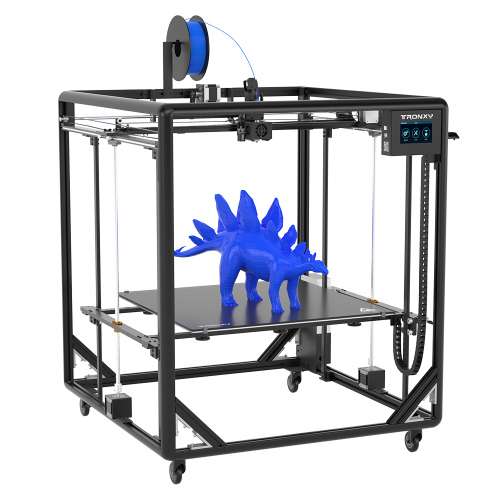

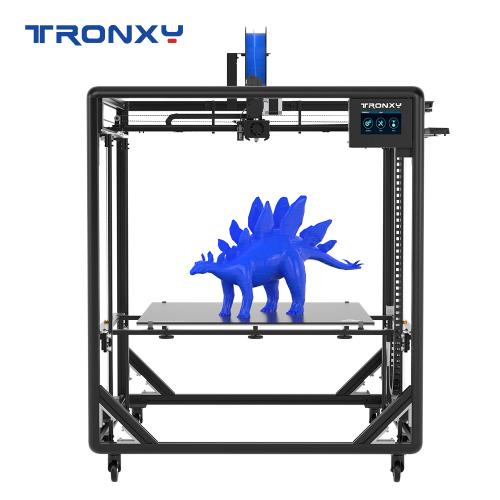

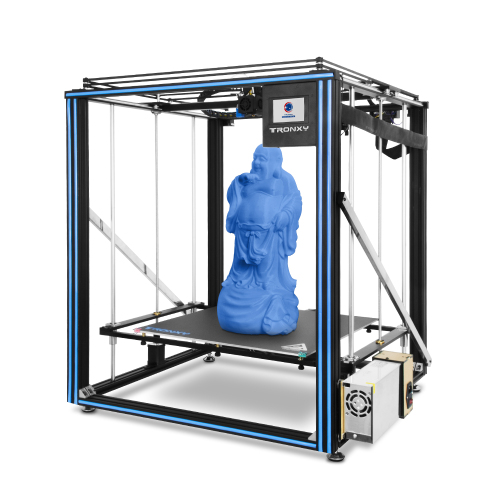

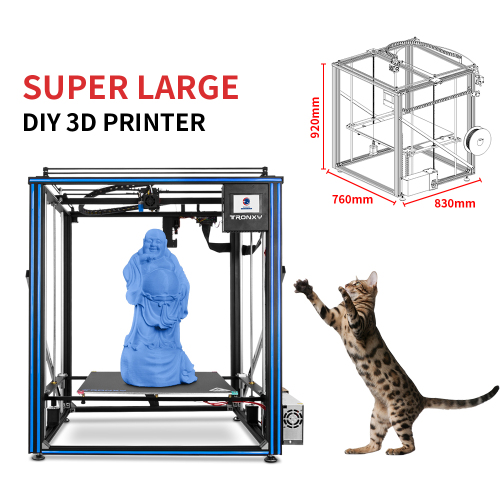

FDM is the most common form of desktop 3D printing in the consumer market. The FDM system consists of a platform extrusion nozzle and a control system that provides a quick and straightforward solution to 3D printing. The thermoplastic filament is heated and deposited in x and y coordinates as the object is built layer-by-layer in a z-direction. FDM printers build objects from the bottom up and typically need support structures if the object has overhanging parts more than a 45° angle. This form of 3D printing is the most cost-effective way for individuals and small businesses to create parts quickly and efficiently. The printers have evolved from bulky, expensive machines to smaller, faster, economical ones that have become the key components for engineering and design departments.

There is a broad choice of FDM 3D printers for every budget, starting at a few hundred dollars. Filament spools are relatively inexpensive, starting from $25 per kilo. These factors made FDM printers so popular among makers and home users.

You can find the best FDM 3D printers here: 2020 Best Tronxy 3D Printers

FDM printers typically use PLA, PETG, or ABS filament. Most FDM printers can handle nylon, PVA, TPU and a variety of PLA blends (mixed with wood, ceramics, metals, carbon fiber, etc.) Filaments are available in various colors. Some manufacturers even offer a service to manufacture RAL colors by demand.

Most FDM printers can use standard filament rolls that are available in two standardized sizes (diameter: 1.75 or 2.85mm) from various sources. A few printers use proprietary filaments or filament boxes – these are typically more expensive than standard rolls but deliver better quality.

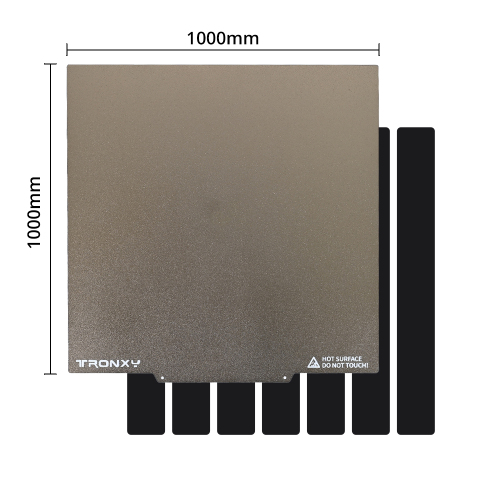

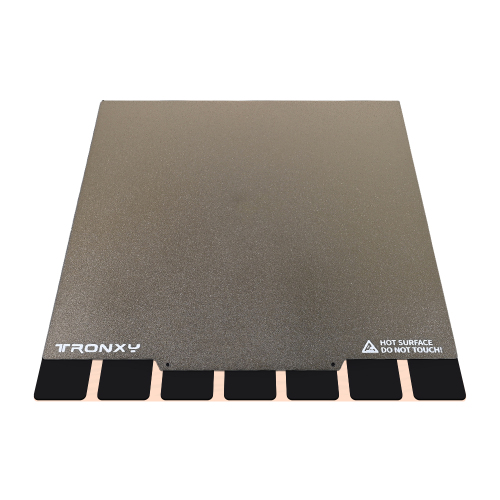

FDM: Adhesion/removal after 3D printing

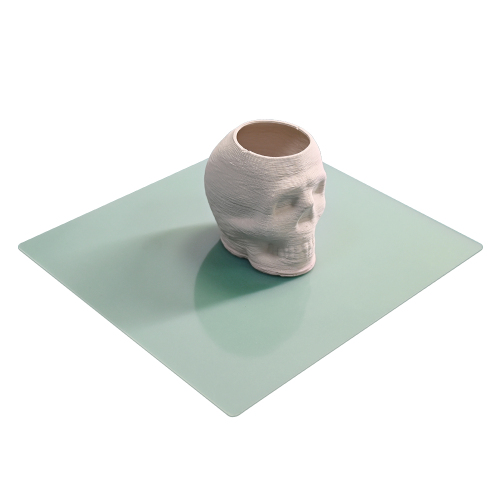

Adhesion to the print bed is a topic when using an FDM printer. Printed objects can be relatively easily removed – if the object sticks to the print bed, a palette knife will do.

FDM: Postprocessing

After printing on an FDM printer you need to remove supports (if the model has overhangs) and excess plastic either with your fingers or a cutting tool. Sanding helps to get smoother surfaces.

FDM: 3D printing costs

Consumable in FDM printers are nozzles and filament rolls. As already mentioned, most FDM printers use the same standardized filament rolls, prices for filament have been declining in the last years. 1 kg of PLA filament can be bought for $25, specialized filaments cost more.

When to use FDM

-

Rapid prototyping

-

Building low-cost models

-

Great for hobbyists and makers

Newsletter

- Company Info

- About Us

- Contact Us

- News Center

- Support Center

- User Center

- Register

- My Account

- My Orders

- Tracking Order

- Forget Password

Copyright © 2012-2023 Tronxy 3D Printer All Rights Reserved.